Use:

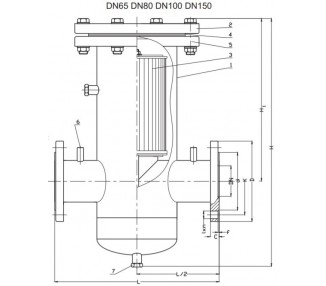

Gas filters type PL 7310 (inclined flow) and type PL 7320 (straight flow) are intended for filtering natural gas (liquid group 1 in accordance with Directive 2014/68 / EU). Filters can be used in overhead installations in vertical or horizontal pipelines.

Technical specification:

All (100%) filters are leak tested. The tests check the exterior and tightness of the bonnet. All production materials are selected to ensure safe operation and prevent sparking and explosion during operation.

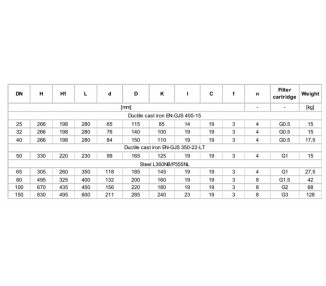

- nominal diameter range (dimensions): DN20 to DN80 [mm]

- the maximum gas flow (under operating conditions) must not exceed 150 m3 / h per square meter of filter element in cellulose filters and 300 m3 / h per square meter of filter element in fabric filters

- PM5 filtration efficiency is 99.9%

- connection flanges are manufactured in accordance with PN-EN 1092-2 (DIN 2501)

Protective coatings:

All internal and external cast iron surfaces are protected with epoxy paint applied electrostatically. The thickness of the anti-corrosion coating is min. 250 μm. The casting surface is pre-treated with epoxy coating in accordance with the appropriate technical staff and the standard PN-EN ISO 12944-5.

Accommodation:

Gas filters type PL 7310 and type PL 7320 can be installed in overhead pipelines, both horizontally and vertically. The listed products are suitable for connection to the flange ends of pipelines whose size is equal to the size of the filter flanges. During installation, it must be ensured that the system does not expose the fittings (filters) to bending, tension and installation stress due to the mass load of the unsupported pipeline. Assemble taking into account the pressure and temperature compensation of the pipeline.

Filters assembled and supplied by the manufacturer are ready for installation in the system. Any disassembly of the filter components may result in a loss of seal. Use proper safety tools of your own and avoid any actions that could cause sparks during all repairs and maintenance and replacement of the filter cartridge.

error Your review appreciation cannot be sent